homemade pellets mill

As making pellets at home becoming more and more popular, homemade pellets mil now plays an increasingly important role in daily life. But how to choose a proper homemade pellets mill?For homemade pellets mill is used for small scale production, a flat die pellet mill will satisfy your need to the machine’s size, weight, yield, energy consumption, and some other requirements.

Take homemade pellets mills developed by our company as an example. If you want to have a machine which can produce 100-200kg pellets each hour, there will be four types of flat die pellet mills for you choosing. They differ from driving modes: diesel engine, electric motor, and PTO. Then you should consider your own situation: is diesel oil or electricity available for you? Where do you want to make pellets, home or farm? After thinking about these problems you can decide which one you want to purchase.

|

|

| Diesel Powered Pellet Mill | Eletric Powered Pellet Mill |

|

|

| PTO Pellet Mill | Gas Powered Pellet Mill |

Homemade Pellets Mills with 120-200kg/h Yield of GEMCO

| Model | Driving Mode | Power | Weight | Packing Size |

|---|---|---|---|---|

| ZLSP 230A | Diesel Engine | 22HP | 280/310kg | 1560*850*1000mm |

| ZLSP 230B | Motor | 11KW | 290/320kg | 1180*540*1000mm |

| ZLSP 230C | Covered Motor | 11KW | 290/320kg | 1200*560*950mm |

| ZLSP 230P | PTO | 22HP | 175/200kg | 1000*540*1020mm |

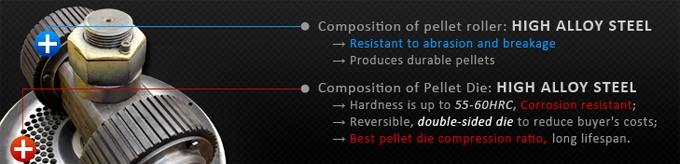

As for materials, some of homemade pellets mills on the market may have certain requirement to pelletizing materials. To pellets mill of GEMCO, they are all powerful in dealing with various materials including those with crude fiber. What you should pay attention to is making the moisture and size of the material as processing regulates.